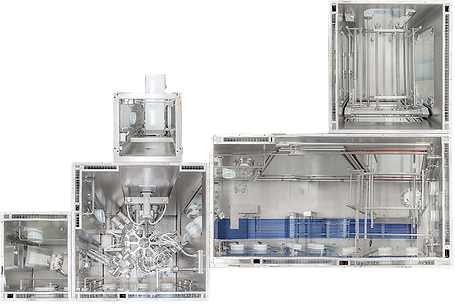

Isolator systems for aseptic filling lines in the pharmaceutical industry

PLÜMAT Maschinenbau designs and manufactures fully integrated aseptic filling and sealing machines combined with advanced pharmaceutical isolator systems.

Together with PLÜMAT UK, specialists in isolator engineering and containment technology, we provide complete aseptic production solutions for the highest requirements in pharmaceutical manufacturing.

Our isolator systems are perfectly aligned with PLÜMAT’s aseptic filling platforms, creating a seamless, highly automated environment that ensures maximum product protection, operator safety, and full GMP compliance.

Why Aseptic Isolator Technology?

Sensitive pharmaceutical products require the highest level of environmental control during filling and sealing processes. Aseptic isolator systems represent the most advanced solution for preventing contamination while maintaining efficient production workflows.

Compared to conventional cleanroom concepts, isolators offer:

-

Significantly reduced contamination risk

-

Stable and controlled aseptic conditions

-

Lower operating costs over long production runs

-

Enhanced operator protection

By physically separating the product area from the surrounding environment, PLÜMAT isolator systems ensure consistent product quality and regulatory compliance.

Fully integrated isolator filling systems by PLÜMAT

At PLÜMAT, isolator technology is not an add-on — it is an integral part of the entire aseptic production concept.

Our integrated approach combines:

-

Aseptic filling and sealing machines by PLÜMAT Maschinenbau

-

Custom-engineered isolator systems by PLÜMAT UK

This ensures perfect interaction between filling technology, containment design, automation and process control.

The result is a highly reliable, efficient and future-proof aseptic production solution from a single source.

Aseptic Filling Machines in

Isolator Environment

PLÜMAT isolator systems can be combined with fully automatic as well as semi-automatic filling solutions, depending on production capacity and application requirements.

Fully automatic systems

BFL Linear Filling Lines in Isolator

Fully automatic linear filling and sealing machines offering flexible output rates, precise dosing and maximum aseptic safety.

BFR Rotary Filling Lines in Isolator

High-performance rotary filling machines designed for continuous aseptic production in compact layouts.

Semi-automatic solutions

BFL006 Aseptic

Flexible semi-automatic filling machine for small batches, pilot production and specialized aseptic processes within isolator or RABS environments.

PLÜMATEX F010 / F014-2 BFU

Compact semi-automatic bag filling system for admixing and dispensing processes, suitable for isolators, RABS and ISO 5 LAF environments.

Isolator vs. RABS – Choosing the right aseptic concept

Both isolators and RABS are used in aseptic production, but isolators offer the highest level of separation between product and operator.

They are particularly suitable for:

-

Highly sensitive products

-

Hazardous or potent substances

-

Extended production runs

PLÜMAT supports customers in selecting the optimal containment solution.

Isolator Engineering by PLÜMAT UK

Founded in 2025, PLÜMAT UK focuses exclusively on pharmaceutical isolator systems.

Its team brings decades of experience in:

-

Isolator engineering and design

-

Containment technology

-

GMP-compliant aseptic environments

-

Customized isolator solutions

Together with PLÜMAT Maschinenbau, this creates perfectly integrated high-end aseptic systems.

Key advantages of PLÜMAT isolator systems

-

Maximum product protection

A fully controlled aseptic environment ensures the highest level of sterility for sensitive pharmaceutical products. -

GMP-compliant design

Engineered according to current GMP guidelines and international pharmaceutical standards. -

High automation level

Minimized manual intervention for stable, efficient and reproducible production processes. -

Seamless machine integration

Isolators and filling machines are perfectly aligned as a unified system. -

Reduced contamination risk

Closed system design significantly lowers particle and microbial exposure. -

Long-term reliability

Robust construction and proven technology ensure long service life and low maintenance.

Each system is tailored to specific customer requirements.

Typical Applications

Ready-to-use pharmaceutical liquids (LVP & SVP)

Aseptic filling of large and small volume parenterals as well as ready-to-use liquid drug products.

Sensitive formulations and biologics

Ideal for highly sensitive products such as biologics, vaccines and high-value pharmaceutical formulations requiring strict contamination control.

Oxygen-sensitive products

Controlled environments for filling solutions that require minimized oxygen exposure to maintain stability and shelf life.

Hazardous or potent substances

Safe containment for products requiring high operator protection, including cytotoxic or highly active compounds.

Clinical trial and small batch production

Flexible systems for pilot lines, development batches and clinical manufacturing.

Sterile compounding and admixture applications

Precise filling of admixture bags and compounded pharmaceutical solutions.

Flexible system designs allow easy adaptation to different container formats, filling volumes and production processes.

Speak to our aseptic experts

Whether a new aseptic production line or modernization of existing plants – PLÜMAT offers integrated isolator solutions for sustainable production success.

Contact our team for a personalized consultation.